Cement for Green Building

26 Sep 2019 - Energy

An innovative and environmentally friendly future with GEOPOLYMERS

References: MEASURE 1.1.2 B2 – INTRODUCTION OF NEW PRODUCTS

CATEGORY: ENERGY

Sub-scope: NEW INNOVATIVE TECHNOLOGIES IN THE FIELD OF ECO INNOVATION (MATERIALS, PROCESSES AND ADVANCED DEVICES IN THE ENERGY-ENVIRONMENTAL AND BIO-BUILDING FIELD)

The relaunch of construction in this historical moment passes through innovative eco-technologies in the energy-environmental and green building fields. The impact of the building process on our territory up to now has been little considered and evaluated, however the production processes of cements and bricks, together with the poor efficiency of the energy insulation systems of the buildings have led to a considerable energy expenditure. In this perspective, it would be interesting to consider the use of innovative materials to be used in the construction sector, which would allow to minimize the impact on the environment and on the territory in order to favor their protection.

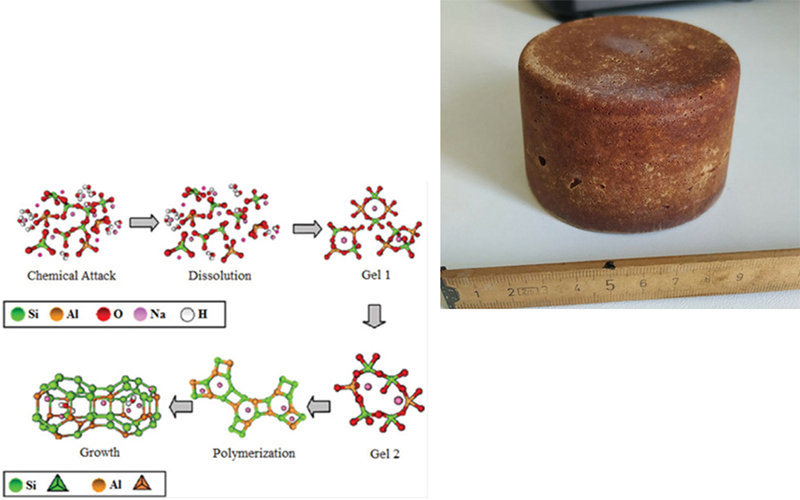

In recent decades, a class of innovative materials, defined as "geopolymers" has aroused the interest of both scientific research and industry. Geopolymers are inorganic polymeric materials with an aluminosilicate base (mineral or industrial waste). Unlike hydraulic cements, geopolymers do not contain hydration water and are processed at low temperatures (T<350 ° C) and can withstand up to 1200 ° C even for long exposures. Their mechanical strength is comparable to that of many traditional high temperature sintered ceramic materials.

The project aims to boost the birth of industry and R&S of geopolymeric materials in Sicily, thus helping to give impetus to the mining sector for the extraction of raw materials to be used (clays, etc.) and to the green building industry sector (industrial waste, etc.), with the design and realization of solutions based on the use of these materials, making the most of their peculiar properties.

Geopolymers are very versatile materials, but what makes them extremely interesting for application purposes is their production simplicity and therefore their low environmental impact. They can be obtained through the preparation of mixtures with variable consistency, adaptable to different types of molding and can be consolidated at low temperature. Precisely in consideration of the low consolidation temperatures and the possibility of using a wide variety of raw materials, including some types of industrial waste, as well as for their longevity linked to chemical inertia, high mechanical resistance and refractoriness, geopolymers are considered eco-compatible or "environmentallyfriendly" materials.

The goal of the following project is to make operational the feasibility study on the reconversion, in Sicilian territory, of the production lines of an industry that currently produces "traditional" concrete in favor of ecological geopolymer concrete.

In the light of the legislative, climate finance and scientific literature consulted, the innovative process that can be achieved through reconversion is desirable and extremely advantageous from an economic and environmental point of view and absolutely consistent with the environmental protection policies implemented by the European community.